Our three pillars, JWWA, JIS and ISO90001

They ensure high quality and reliability based on strict management

Our manufacturing practices that render products of high reliability and quality are underscored by a quality management system that meets JWWA, JIS and ISO9001requirements. State-of-the-art equipment for conducting live flow experiments and various analyzers and testers support production by ensuring high quality and safety.

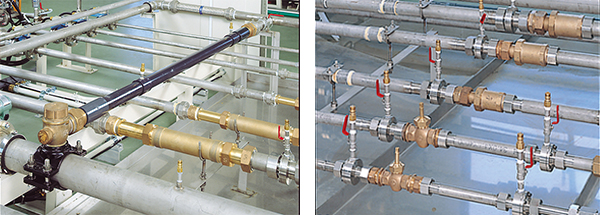

In addition to a water circulation system, low-noise pumps made in German are used. This extremely effective system is comprised of pipelines 13 to 50 mm and 100 mm in nominal diameter and precision high-speed measuring instruments.

Scenes of a flow test for multiple products (stop valves, snap taps, pressure reducing valves, check valves, saddle with an integral ferrule valve, etc.) that Komei proudly supplies.

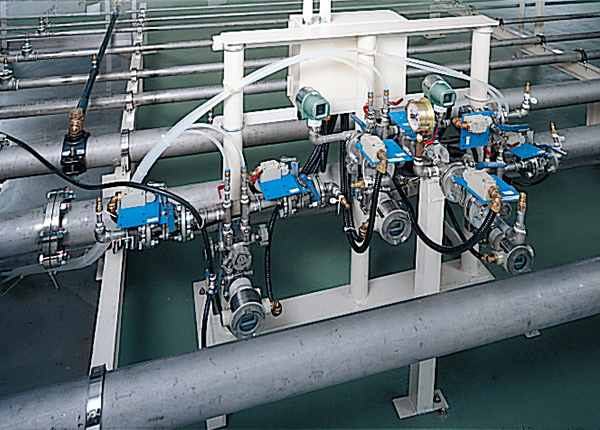

Digital measuring equipment consisting of high-performance components. It is applicable to water hammer tests that require high-speed measurement, as well as pressure tests and differential pressure tests.

Quiet clean measuring room that enables real-time remote monitoring of measurements from a PC. We have established a safe 2-way system, so that manual measurement is enabled even if the PC does not work.

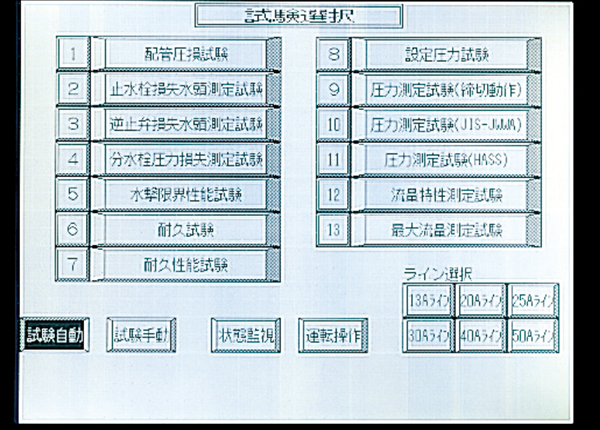

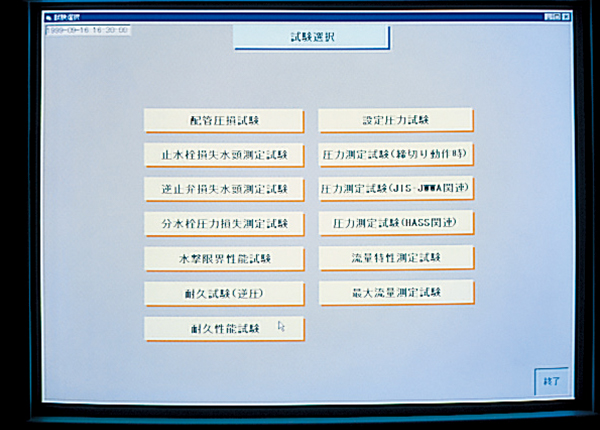

Test selection screen

Tests and pipe diameters can be selected from a soft LCD touch panel.

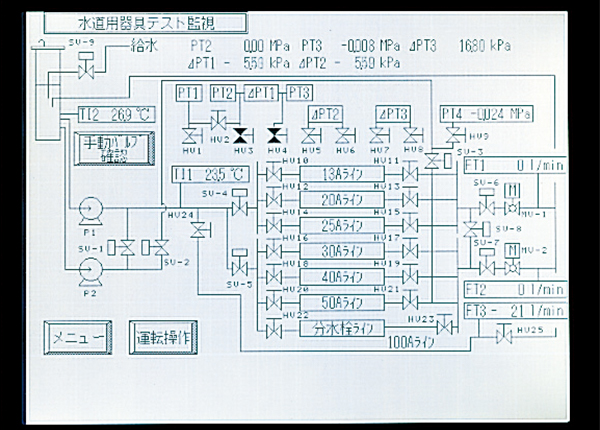

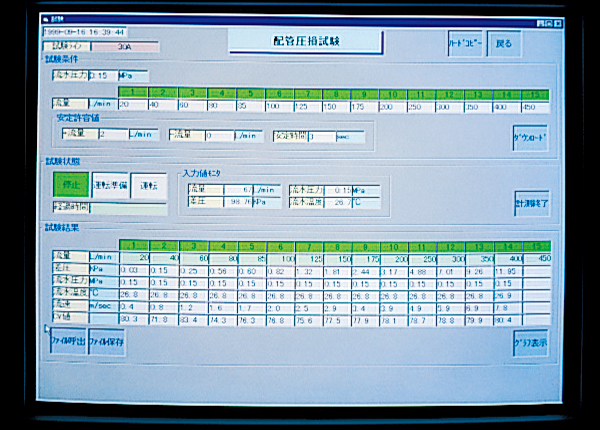

Control screen

Displays a live flow chart that enables operators to identify trouble in units under automatic monitoring and line configuration with selected pipe diameters at a glance.

Test selection screen

Initial screen for selecting tests.

The screen shows test conditions and manual operations dictated by JWWA and other standards, thus enabling a wide range of tests and measurements.

Test tracking screen

Easy-to-see test tracking screen that automatically displays measurement data after condition matching as well as real-time measurement data, with the minimum-required test conditions. Measurement data can be quickly plotted out.

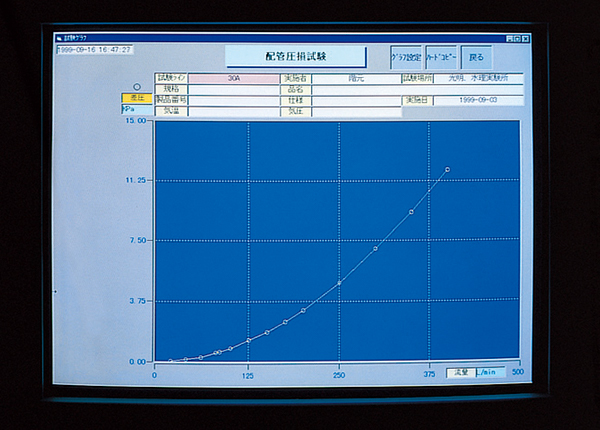

Analysis graph

Instantaneously plots test results on graphs, so that performance of the piping under testing can be confirmed at once.

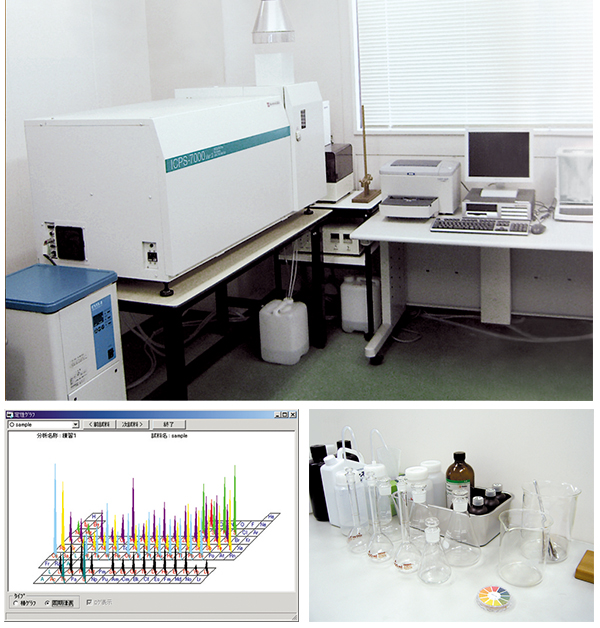

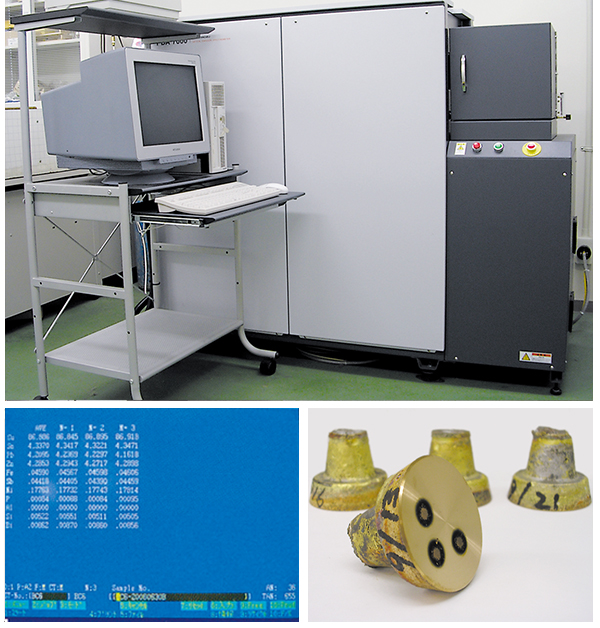

This equipment is adopted to ensure that products can be safely used. Qualitative and quantitative analyses are done using the easy-to-operate software. The user can conduct qualitative analyses simply by entering a group name and sample name. In quantitative analyses, the user can easily obtain results just by setting sample concentration on a standard curve.

With a spectro-chemical analyzer, multiple elements contained in metal can be simultaneously and quickly analyzed to a high degree of accuracy. This analyzer is applicable to a wide range of materials from cast bronze and copper alloy (lead-free) under JIS, as well as stainless steel and cast iron. Measuring range can even be set for trace concentration. This equipment analyzes samples taken for each molten material, so as to control composition.

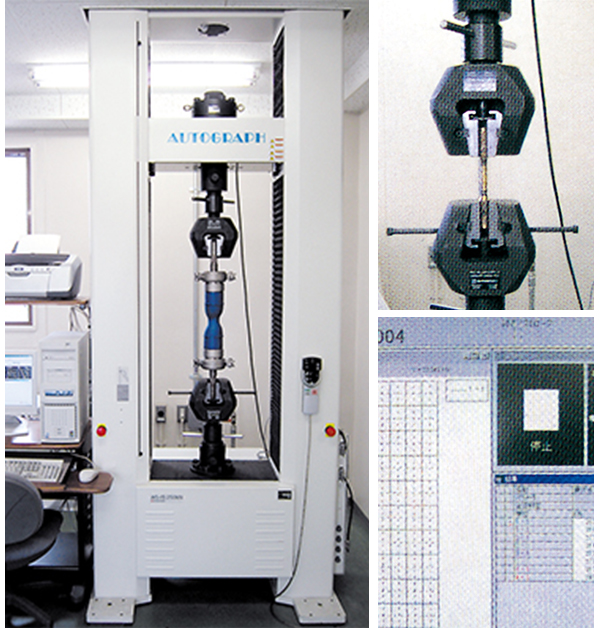

This highly-functional tester performs standardized material tests (tensile tests, compression tests, bend tests, peel tests, etc.) at high speed and to a high degree of accuracy. Tests can also be controlled from a PC. This equipment has the following features.

[1] Highly rigid frame that ensures stability during long test

[2] High-speed sampling that helps to pinpoint true values

[3] Applicable to various material tests at a wide range of test speeds

To enhance product reliability by way of quality improvement, Komei first acquired certification from JWWA (Japan Water Works Association) as an authorized inspection facility in 1959. Then, our factory was authorized to display the JIS (Japanese Industrial Standard) mark in 1969, which granted us certification under the new JIS mark system after the Industrial Standardization Act was amended in 2008. Furthermore, following company-wide efforts in TQC (Total Quality Control), we acquired certification under ISO9001 (quality assurance standard of International Organization for Standardization). Thus, we have established a higher-grade quality control system. The attentiveness to problems by each and every employee and constant efforts for quality improvement have made the Komei brand what it is today.